Keep your plant running — and your community powered. When equipment failure is not an option, the world’s leading power plant operators trust Philadelphia Gear.

For the past 100 years, we’ve supported every aspect of the power generation process, helping operators avoid downtime and associated fees. And when plants want to move towards sustainable energy, we provide the engineering expertise and partnership to succeed.

From larger coal, gas, and nuclear-based plants to smaller wind-powered plants, we run to the problem — providing the manufacturing, engineering, and 24/7 onsite support to ensure stable, efficient performance.

TRUSTED POWER PLANT SOLUTIONS ACROSS FIVE PLANT TYPES

Find expert drivetrain support for your plant’s specific application.

Gas-fired plants

When supplying a quarter of the world’s energy, leading gas-fired power plants demand reliability from their compressors, turbines, and generators — all supported and maintained by Philadelphia Gear.

Coal-fired plants

Whether crushing coal, preheating air used in boiler combustion, or running pumps that supply essential water, Philadelphia Gear equipment is critical in keeping coal-fired plants running smoothly.

Learn More

Nuclear plants

Access support for boiler feed pump gear drives and cooling tower gear drives — plus support from our sister facility, Schulz Electric, for specialized safety-related electric motor services.

Hydroelectric plants

Unleash the full potential of hydropower with our end-to-end electro-mechanical drivetrain support. Across the country, stations of all sizes rely on our design and manufacturing, repairs, parts, and more.

Learn More

Wind Farms

Ensure uptime and minimize operational costs. Our sister team at H&N Wind supports up-tower services , generator and specialized wye ring repair, critical parts replacements, oil changes, and more.

COMPLETE SUPPORT FOR YOUR POWER GENERATION APPLICATION

- Accessory gear drives

- Air preheater gear drives

- Atomizer gear drives

- Ball mill drives

- Bevel gears

- Bevel-helical gears

- Boiler feed pump gear drives

- Bull gears

- Classifier gear drives

- Condensate pump gear drives

- Conveyor gear drives

- Cooling tower gear drives

- Double reduction bevel-planetary gear drives

- Double reduction, bevel-vertical parallel shaft gear drives

- Epicyclic gear drives

- Frame 5 (GE MS5001P) gear drives

- Frame 5 GE load boxes

- Frame 6 (GE MS6001B) gear drives

- Frame 6 GE load boxes

- Gas turbine equipment

- Gas turbine gear drives

- Gas turbine skids

- GE load boxes

- Gear drive design

- Gear drive repair

- Gear drive parts

- Gearbox design

- Gearbox parts

- Gearbox repair

- Generator gear drives

- Girth gears

- High-speed gear drives

- Horizontal offset parallel shaft gear drives

- Horizontally offset parallel shaft gear drives

- Hydroturbine gear drives

- Induced fan gear drives

- Load boxes

- Load gear drives

- Low-speed gear drives

- MPS-89 gear drives

- Onsite technical services for gears

- Parallel shaft gear drives

- Pinion gears

- Planetary gear drives

- Pulverizer gear drives

- Single reduction, single helical gearing

- Steam turbine equipment

- Steam turbine gear drives

- Steam turbine skids

- Synchrotorque

- Wind turbine gear drives

- Worm gears

- Worm helical gears

JOIN HUNDREDS OF SATISFIED CUSTOMERS

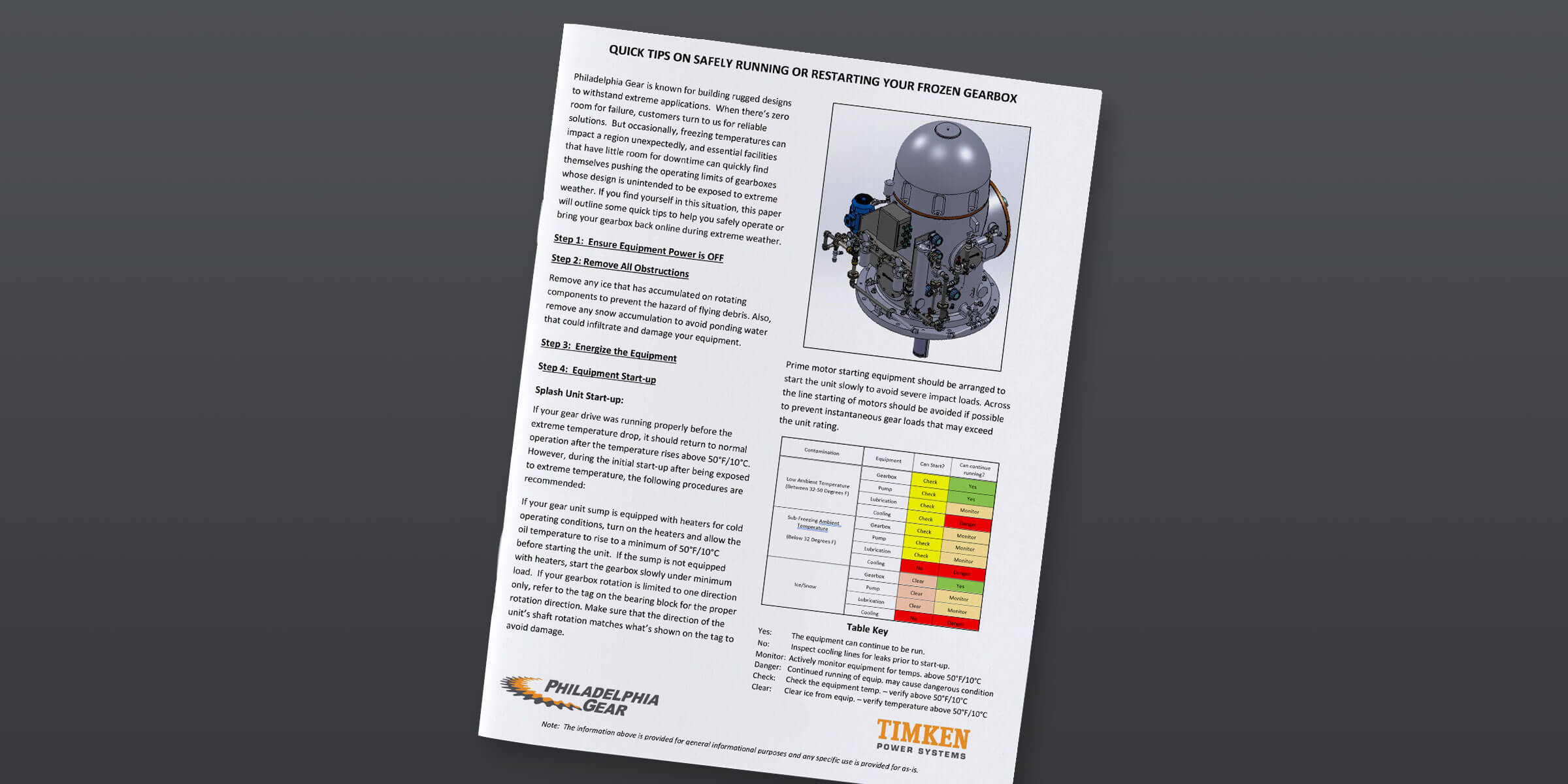

EXPLORE POWER GENERATION RESOURCES

Configuration Tool

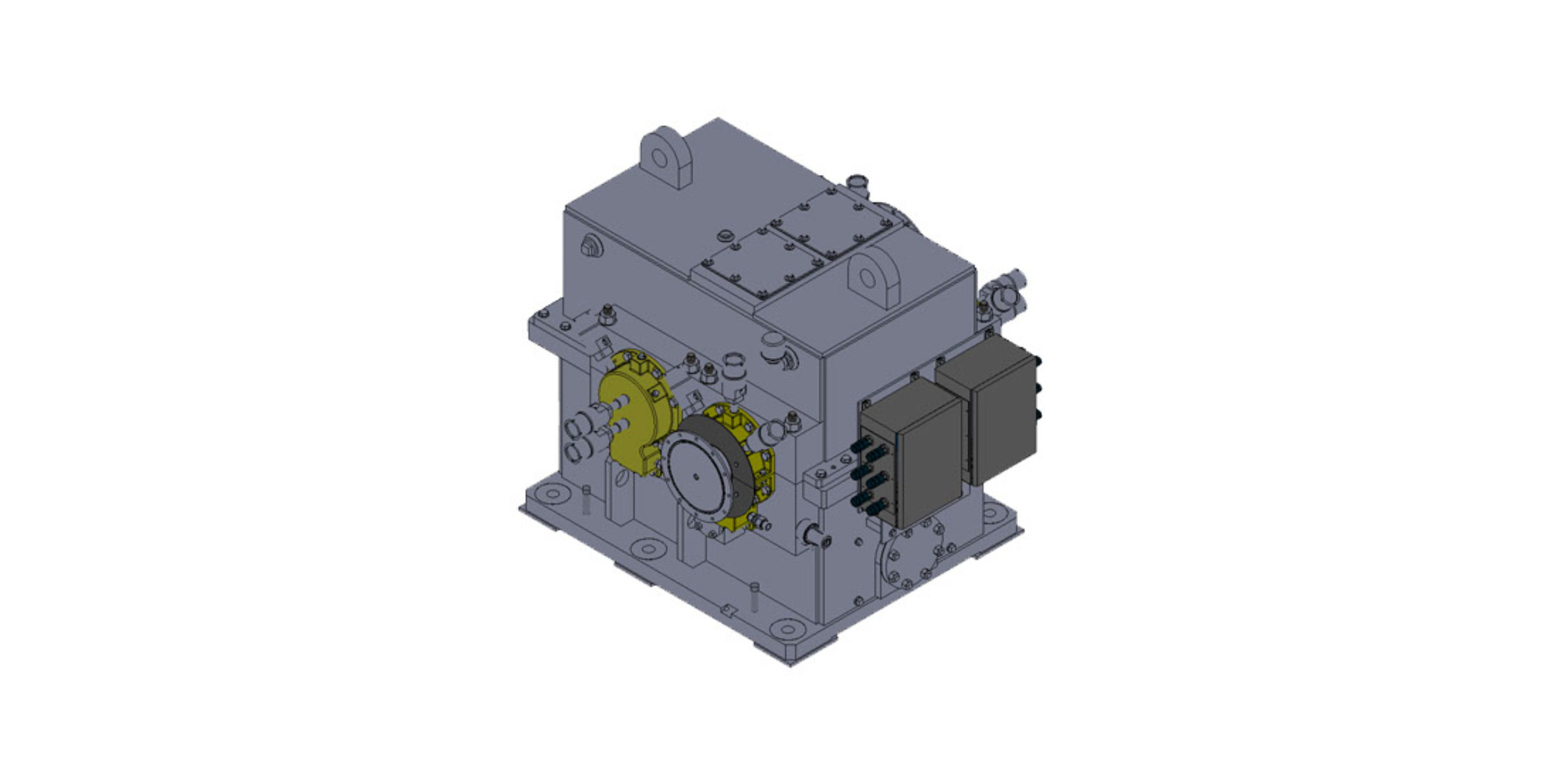

PROVEN SOLUTIONS FOR YOUR COMPLETE DRIVETRAIN SYSTEMPhiladelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1

Gear drive repair

-

2

New and replacement gear drive expertise

-

3

Gear drive replacement parts

-

4

Onsite technical services

-

5

Drivetrain solutions

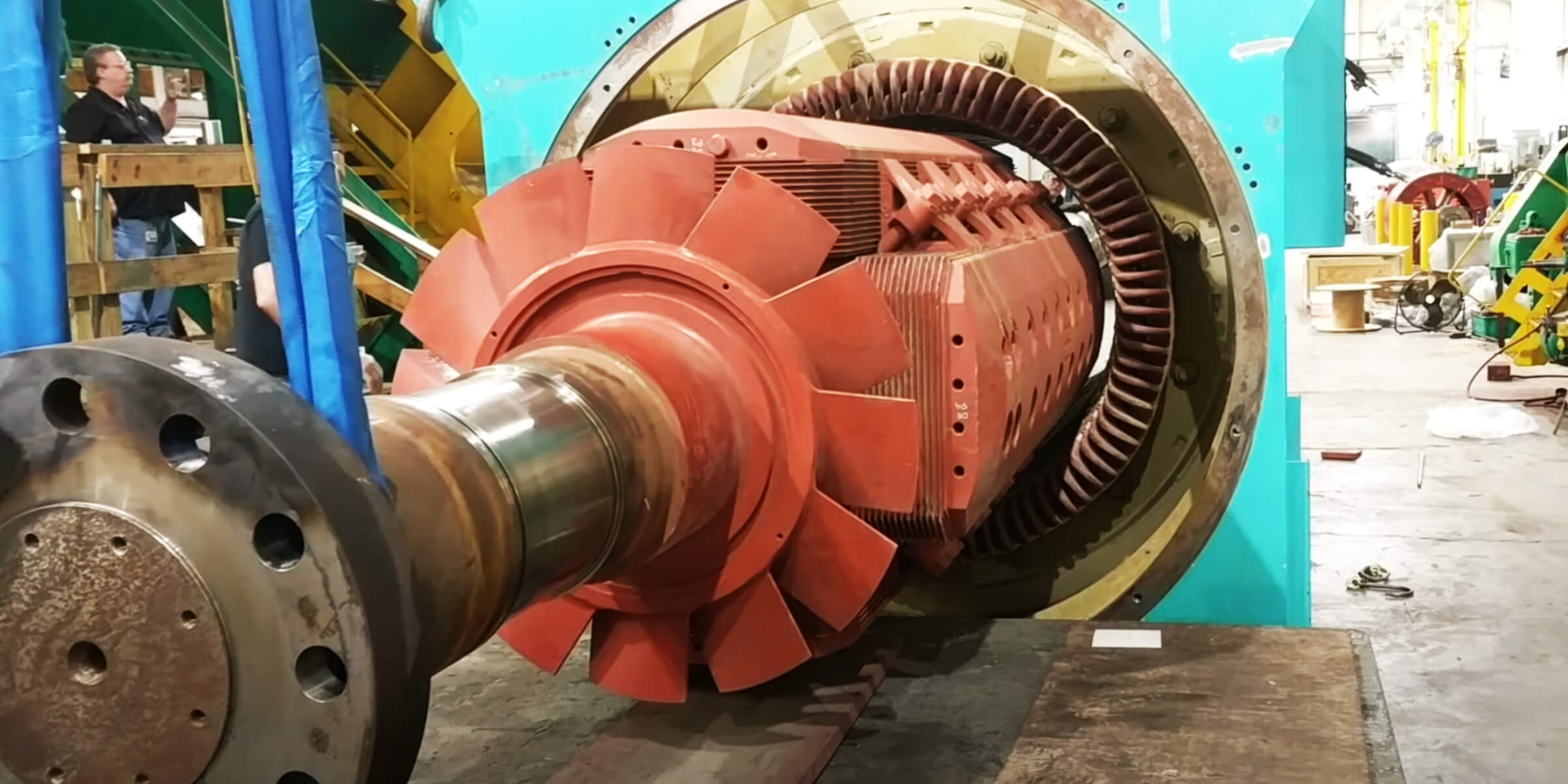

1 Gear drive repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gear drive expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gear drive replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gear drive installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

Philadelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1Gear drive repair

-

2New and replacement gear drive expertise

-

3Gear drive replacement parts

-

4Onsite technical services

-

5Drivetrain solutions

1 Gear drive repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gear drive expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gear drive replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gear drive installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

KEEP YOUR PLANT AT PEAK PERFORMANCE. CONTACT OUR EXPERTS TODAY. We’re standing by to help with your most complex power generation challenges. Connect with one of our expert specialists today.

CONTACT US

We’re standing by to help with your most complex power generation challenges. Connect with one of our expert specialists today.